JS1500 Concrete MIxing Plant

Model: HLS90 Concrete Mixing Station Type: Inclined belt

Productivity: 90 cbm/hour Power of Mixer: 2*30KW

Matched Mixer: JS1500 Total power: 110kw

Diacharge height: 4.2M Capacity of Inclined Belt: 550t/h

JS1500 Concrete Mixing Plant

Batching system

A wide range of aggregates can be weighed at the same time with high efficiency.

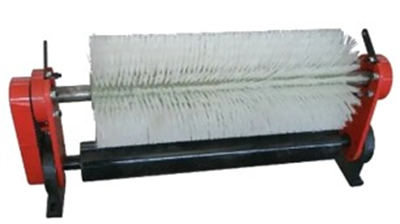

The belt conveyor is equipped with a spiral tensioning device at the end of the belt conveyor, which can adjust the belt tension at any time to prevent the belt from slipping and running off, ensuring efficient operation.

The head of the belt conveyor is equipped with a material stopping device, which effectively prevents spilling of material.

The aggregate hopper and the side wall of the aggregate weigher are equipped with vibrators, which facilitate quick weighing and quick discharge.

Aggregate conveying

Electric drums with high load-bearing capacity, smooth running, low noise and long service life.

Enclosed conveying, dustproof and anti-falling material, efficient and environmentally friendly.

Double-sided walking platform, easy maintenance and overhaul.

Forward tilting carrier rollers, automatic centre adjustment, effective correction of belt runout.

Pull rope emergency stop switch, safe and reliable operation.

Metering system

Aggregate metering: pressure type sensor, accurate metering; each aggregate is measured separately, and coarse and fine weighing can be achieved.

Powder metering: pressure type sensor, precise metering, smooth running, safe and reliable.

Cement metering: pressure type sensor, accurate metering, metering accuracy ±1%, smooth operation, safe and reliable.

Additive metering: pressure type sensor, accurate metering.

Water metering: pressure type sensor, accurate metering, short water discharge time, high efficiency.

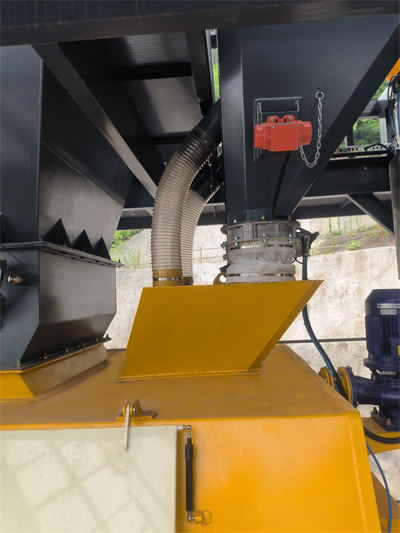

Dust removal system

Both the main machine and the silo roof adopt pulse type dust collector, which is environmentally friendly and efficient.

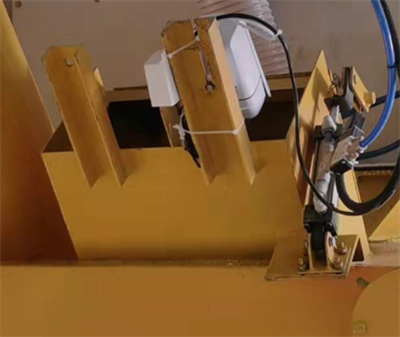

Mixing system

Shaft end seal, using German BHS structure, long service life.

The liner and blades are made of high chrome and wear-resistant alloy cast iron, with reasonable angle design, efficient and fast mixing and long service life.

The shaft end is equipped with a fully automatic sealing and oiling lubrication system.

The hydraulic oil pump controls the feeding gate, which can be opened in three levels and is equipped with a manual gate opening device for smooth and noiseless operation.

Control system

Schneide (Germany) component control cabinet, can realize automatic control, semi-automatic control and manual control. With recipe input storage, automatic correction of splash error, parameter adjustment, scale calibration, automatic fault diagnosis, automatic alarm, real-time printing and other functions.

Installation and after-sales service

Modular design, easy installation and maintenance, quick relocation and transportation.

Model | HLS60 | HLS90 | HLS120 | HLS180 | HLS240 | ||

Rated Productivity(m³/h) | 60 | 90 | 120 | 180 | 240 | ||

Mixer | Mode | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | |

Driving Power (KW) | 2*18.5 | 2*30 | 2*37 | 2*55 | 2*65 | ||

Discharge Capacity (L) | 1000 | 1500 | 2000 | 3000 | 4000 | ||

Max Aggregate Size (MM) | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ||

Batching Machinery Size (m³) | 15 | 15 | 20 | 25 | 40(underground) | ||

Measuring Accuracy | Aggregate | 2% | 2% | 2% | 2% | 2% | |

Cement | 1% | 1% | 1% | 1% | 1% | ||

Water | 1% | 1% | 1% | 1% | 1% | ||

Additive | 1% | 1% | 1% | 1% | 1% | ||

Maximum Weighing (kg) | Cement | 800 | 1000 | 1000 | 1800 | 2400 | |

Water | 400 | 400 | 500 | 800 | 1000 | ||

Additive | 25 | 25 | 40 | 70 | 100 | ||

Discharge Height (M) | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | ||

Total Power(kw) | 90 | 125 | 160 | 200 | 270 | ||

Detailed Information:

First: The main station dust collecting

1. Adopt pulse dust collector to actively collect the dust generated by the equipment

2. Dust collector is placed on the top of the middle storage bin, dust removal efficiency reaches 99.9%.

3. Automatic pulse cleaning of the dust collected by the filter bag to avoid secondary dust pollution

4. Open structure, easy to repair and maintain

Second. Low noise

1. Mixer legs are equipped with shock absorbing pads to reduce the vibration generated by the operation of the mixer and reduce the noise of the equipment

2. The sound insulation effect of high quality rock wool board is more than 50% higher than the traditional one.

3. The use of screw air compressor, low noise, large air volume, low failure rate

4. Ground bin batching machine, significantly reduce the noise generated by aggregate measurement

Third. Famous brand accessories

Fourth:

The main machine is equipped with a camera to monitor the internal situation of the main machine in real time; it can be equipped with a high-pressure cleaning device to reduce the difficulties of workers cleaning the mixer and the downtime caused by holding the shaft.

Related News

Submitted successfully

We will contact you as soon as possible